大连欣科机器有限公司

联系人:李经理

手 机:135-0425-2328

电 话:0411-89815039

传 真:0411-89815039

地 址:大连庄河市衣屯工业园区

邮 箱:18241106665@163.com

网址:www.dlxkjq.cn

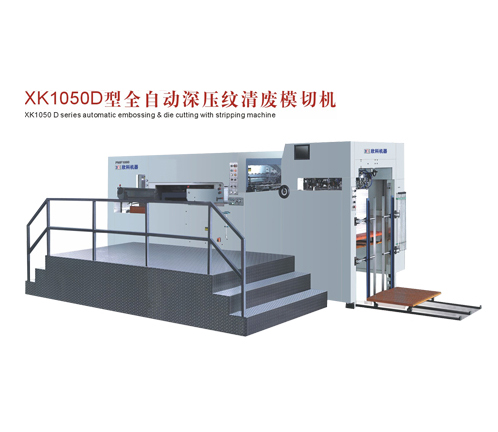

XK1050D型全自动深压纹清废模切机机器主要特点:

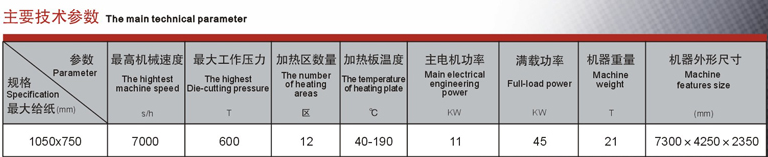

1、全自动模切机上平台采用12个加热温区,每个温区的温度可以单独调控(40-190℃)加热温度均匀。用于热村纹、热压凹凸、热压痕等热压工艺。

2、四吸五送九个吸嘴的给纸头,吸纸强力、送纸稳定,吸嘴可配合纸张的变化状况不停机调理吸纸高度、角度和吸风量,实现厚薄兼顾、办理纸准确平稳。

3、预堆码纸和主副给纸机构,买现不停机连续给纸。

4、采用PCL电脑程序控,井在操作面、收纸面二处分别装有人机界面显示时时监控机器的运转状态,井对电脑程序控制器的输入、出点及督种故障进行动态监控,在这二处装有人机界面触摸屏对排除故障及操作非常方便

5、热压蜂窝版、刀模版框、模切钢板采用气动锁板定位,精度准确、操作方便。

6、采用高强度铝合金牙排,叼纸平稳,有效防止牙排动。牙排的前后定位增加了可调装置,牙排定位精度因主链条或机件磨损误差可微调补偿。

7、左右模切主塘板、上平台、动平台、底台等承載横切压力的关键部件,用耐压高强度球铸铁高溫整体造而成,井经长时间去应力回火、时效处理,可保证在高压力横切时不变形、压力平稳。

8、循环润滑油空调恒温冷却系统可保证主传动内疗关节润滑效果。强制自润滑系统,确保主传动内部供油正常,无油自动停机。定时润滑系控制各润滑点进行定时定量注油润滑。

The main features of XK1050D automatic deep embossing die cutting machine are as follows:

1. Twelve heating temperature zones are used on the platform of automatic die-cutting machine. The temperature of each temperature zone can be adjusted and controlled separately (40-190 C) and the heating temperature is uniform. It is used for hot pressing processes such as hot village pattern, hot pressing concave convex and hot indentation.

2. The paper feeding head of four suction, five suction and nine suction nozzles has strong suction force and stable feeding. The suction nozzle can adjust the height, angle and air suction volume of paper suction without stopping, so as to realize the consideration of thickness and to handle paper accurately and smoothly.

3. Pre-stacking paper and main and auxiliary paper feeding mechanism, buy continuous paper feeding without stopping.

4. Using PCL computer program control, the well can monitor the running state of the machine when it is equipped with the human-machine interface display on the operation surface and the paper receiving surface respectively. The well can dynamically monitor the input, exit and supervisory faults of the computer program controller. It is very convenient for troubleshooting and operation to install the touch screen of the human-machine interface in these two places.

5. Hot-pressed honeycomb plate, knife template frame and die-cutting steel plate are positioned by pneumatic locking plate, which is accurate and easy to operate.

6. Use high strength aluminium alloy teeth row, holding paper smoothly, effectively prevent teeth row. The adjustable device is added to the front and back positioning of the tooth platoon, and the positioning accuracy of the tooth platoon can be adjusted and compensated by the wear error of the main chain or machine parts.

7. The key components bearing transverse shear pressure, such as the main pond plate, upper platform, moving platform and bottom platform, are integrally made of high-temperature high-pressure high-strength ductile iron. After long time stress-relieving tempering and aging treatment, the well can ensure no distortion and stable pressure in high-pressure transverse shear.

8. The constant temperature cooling system of circulating lubricating oil air conditioning can ensure the lubrication effect of the main drive internal therapy joint. Forced self-lubrication system ensures normal oil supply in the main drive and automatic shutdown without oil. Timing lubrication system controls each lubrication point for timing and quantitative oil injection lubrication.

感谢您来到大连欣科机器有限公司,若您有合作意向,请您为我们留言或使用以下方式联系我们, 我们将尽快给你回复,并为您提供真诚的服务,谢谢。 | ||

联系人:李经理 手 机:13504252328 电 话:0411-89815039 传 真:0411-89815039 | 地 址:大连庄河市衣屯工业园区 Q Q:1569026530 邮 箱:18241106665@163.com 网 址:www.dlxkjq.cn | (扫一扫关注手机站) |